The Solution - Waste Plastic to Fuel Production Unit

The problem

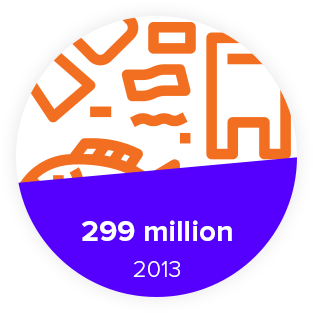

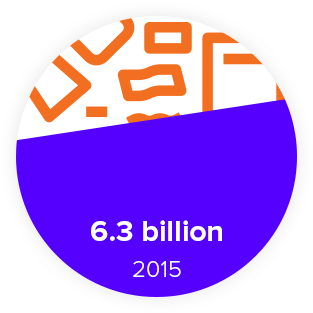

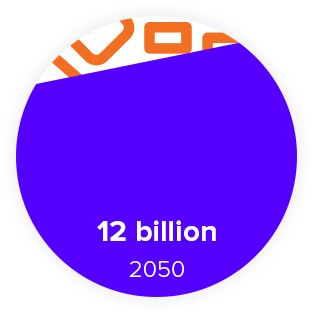

An estimated 6.3 billion tons of plastic waste had been generated as of 2015, of which only 9% was recycled. If current plastic production and waste management trends continue, 12 billion tons of plastic will be in landfills and the natural environment by 2050. Global plastic production was reported to be around 299 million metric tons in 2013, increasing to 335 million metric tons in 2016.

It has been calculated that 275 million metric tons of plastic waste was generated in 192 coastal countries in 2010, with up to 12.7 million tons entering the ocean in a single year. Following this trend, the total weight of plastic in the oceans will exceed the weight of fish by 2050. The United Nations reported that the approximate environmental damage caused plastic to marine ecosystems comes to 13 billion US Dollars.

Fuels and Electricity

1. The petroleum

The petroleum industry, also known as the oil industry or the oil patch, includes the global processes of exploration, extraction, refining, transporting (often by oil tankers and pipelines), and marketing of petroleum products.

The largest volume products of the industry are fuel oil and gasoline (petrol). Petroleum (oil) is also the raw material for many chemical products, including pharmaceuticals, solvents, fertilizers, pesticides, synthetic fragrances, and plastics.

Water pollution

Some petroleum industry operations have been responsible for water pollution through by-products of refining and oil spills. Leaks from underground tanks and abandoned refineries may also contaminate groundwater in surrounding areas.

air pollution

The industry is the largest industrial source of emissions of volatile organic compounds (VOCs), a group of chemicals that contribute to the formation of ground-level ozone(smog).The combustion of fossil fuels produces greenhouse gases and other air pollutants as by-products.

Climate change

The greenhouse gases due to fossil fuels drive global warming. Already in 1959, at a symposium organized by the American Petroleum Institute for the centennial of the American oil industry, the physicist Edward Teller warned then of the danger of global climate change.

2. electricity

An electric or hybrid car is an automobile that is propelled by one or more electric motors, using energy stored in rechargeable batteries. Electric cars have several benefits over conventional internal combustion engine automobiles, including a significant reduction of local air pollution, as they do not directly emit pollutants such as particulates (soot), volatile organic compounds, hydrocarbons, carbon monoxide, ozone, lead, and various oxides of nitrogen.

The use of such a vehicle is more environmentally friendly than conventional petrol or diesel, while their range is considerably shorter and no suitable filling station infrastructure is available.

However, depending on the assumption to create the heart of the electric or hybrid car which is the battery itself, are either a lot less, equally or sometimes even a lot more polluting than engine powered traditional cars.

Researchers are finding that battery production for electric cars ultimately produces more carbon dioxide – up to 74 percent more — than an efficient conventional car if those batteries are produced in a factory powered by fossil fuels. One problem with current lithium-ion battery production – a battery that weighs around 1,000 pounds and is the single most expensive component in an EV – is that the metals to build the battery are mined in just a handful of countries, using methods that are far from environmentally friendly.

The solution

Waste Plastic to Fuel Production Unit

Our Partner company in collaboration with prominent researchers from Thailand’s prestigious Chulalongkorn University, and with support from the Ministry of Energy, has been actively involved in research and development of pyrolysis technologies since the 1990’s.

We are establishing our Waste Plastic to Fuel Production in Thailand and it has the capacity to produce 15,000 liters of crude oil equivalent per day, per module, while disposing of 20,000 kilograms of waste plastic. This is the 5. generation of the machine and applies pyrolysis technology for converting waste plastics into high quality synthetic fuel using an innovative continuous process which produces no pollution whatsoever. Our pyrolysis crude oil which is equivalent to sweet or light crude, but of superior quality due to low bitumen content. Pyrolysis crude oil can be used to power low-speed diesel engines, or further refined to produce EN590 grade, low carbon diesel.

Viability of our business and production model has been proven with genuine use cases, both through the sale of pyrolysis fuel oil for industrial machinery and agricultural equipment, and the diesel produced being provided to the BMTA – one of the largest bus companies in Thailand.

In all cases our fuel has been confirmed to be of excellent quality, drawing a satisfactory response from consumers. The greatest demand for our product is from refineries due to the high diesel yield it delivers.

Do you find this interesting?

If you want to be a part of this business, or get to know more about the project please contact us.

NEXT